What Is Welding, What Are Common Types, and How Does Welding Work?

What is Welding?

The Purpose of Welding

Stated as plainly as possible, the purpose of welding is to join objects together.

While it is possible to weld plastics (specifically thermoplastic), NaiMor does not weld anything other than metal.

Welding is used in pretty much every manufacturing and construction field. In fact, our modern world of skyscrapers, cars, ships, and airplanes would not exist without welding.

Welding Basics

Welding works by fusing two similar metals directly together through heat, pressure, or both, thus forming a join, or weld, as the parts cool. This completed welded joint may also be referred to as a weldment.

During the welding process, parts are combined by melting a filler metal (such as steel) and the base metals, which causes all to combine and forms a more secure and sturdier bond at the welding joint.

The parts that are joined are known as a parent material. And the material added to help form the join is called filler or consumable. These may also be referred to as parent plate or pipe, filler wire, consumable electrode, and other terms.

Consumable material is typically of similar metal composition to the parent material. However, there are occasions when the filler material needs to be different.

Welding requires steady hands and an eye for detail. As the filler melts, the welder must continuously feed the filler into the joint using small, steady, back and forth motions. Going too fast or slow, or holding the welding stick incorrectly can create poor welds, which won’t hold as well. Not to mention, it won't look good!

Common Types of Welding

There are more than a dozen types of welding processes, however only four types of welding are commonly used. These include MIG, TIG, Stick, and flux-cored arc welding. Each welding type comes with certain advantages and disadvantages. NaiMor employs welders who have excellent welding techniques to best serve our customers.

Arc Welding

Arc welding uses an electrical arc to melt metal and uses either AC or DC power. This electrical arc is used to melt the work materials, a consumable electrode and the parent metals, in order to permanently join two similar metals together. Arc welding is used to produce a very concentrated, narrow weld point.

Arc welding consists of MIG, TIG, and Stick.

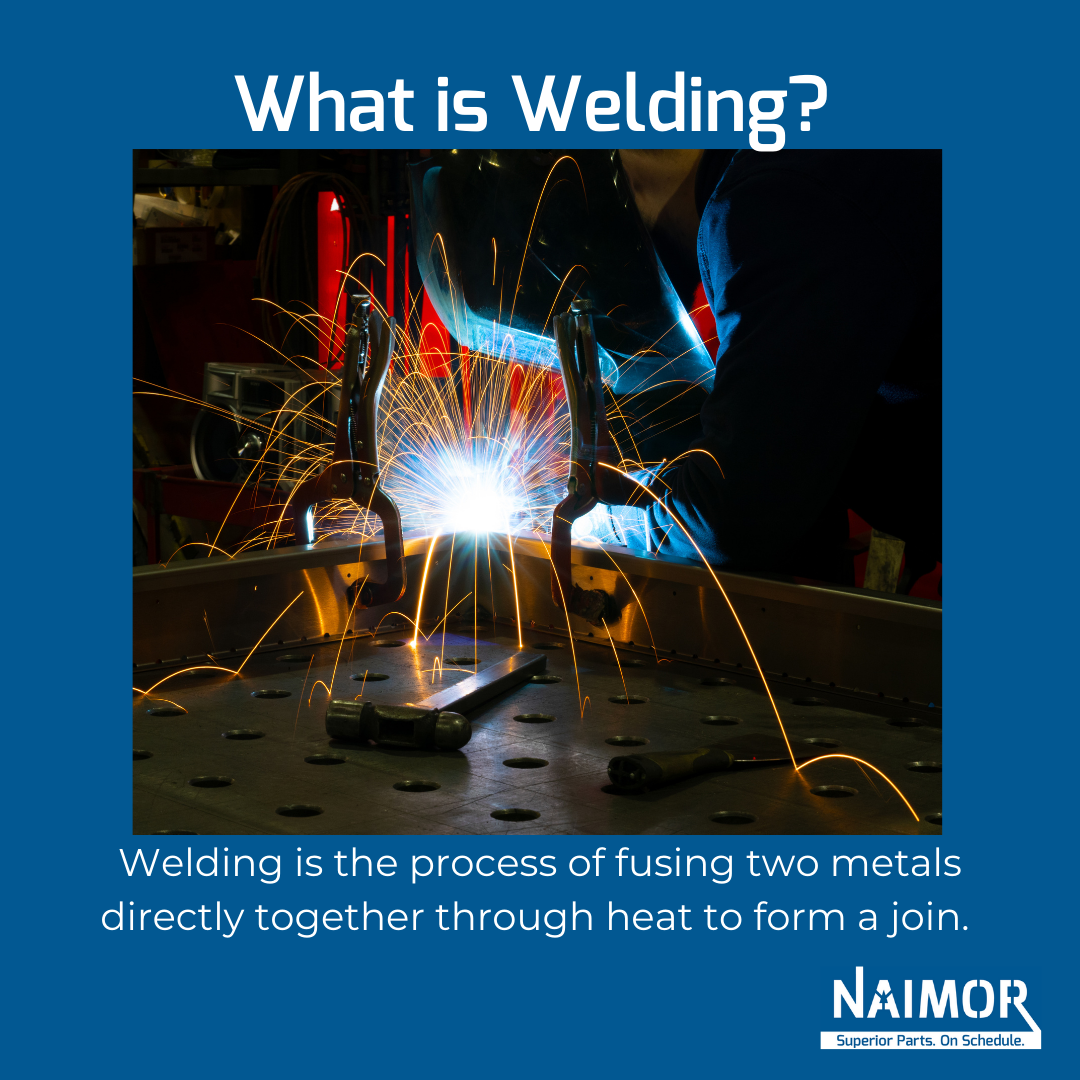

MIG Welding

MIG welding, aka gas metal arc welding (GMAW), can be managed with one hand because there is wire that is fed continuously through the nozzle by a feed motor. This wire is called an electrode and it is the filler material that permanently joins two similar metal parts together.

An inert gas flows around the contact tube to create a shield around the arc. MIG equals metal inert gas. See image 1 for an illustrated explanation of MIG welding.

Image 1. An illustration of how MIG welding works.

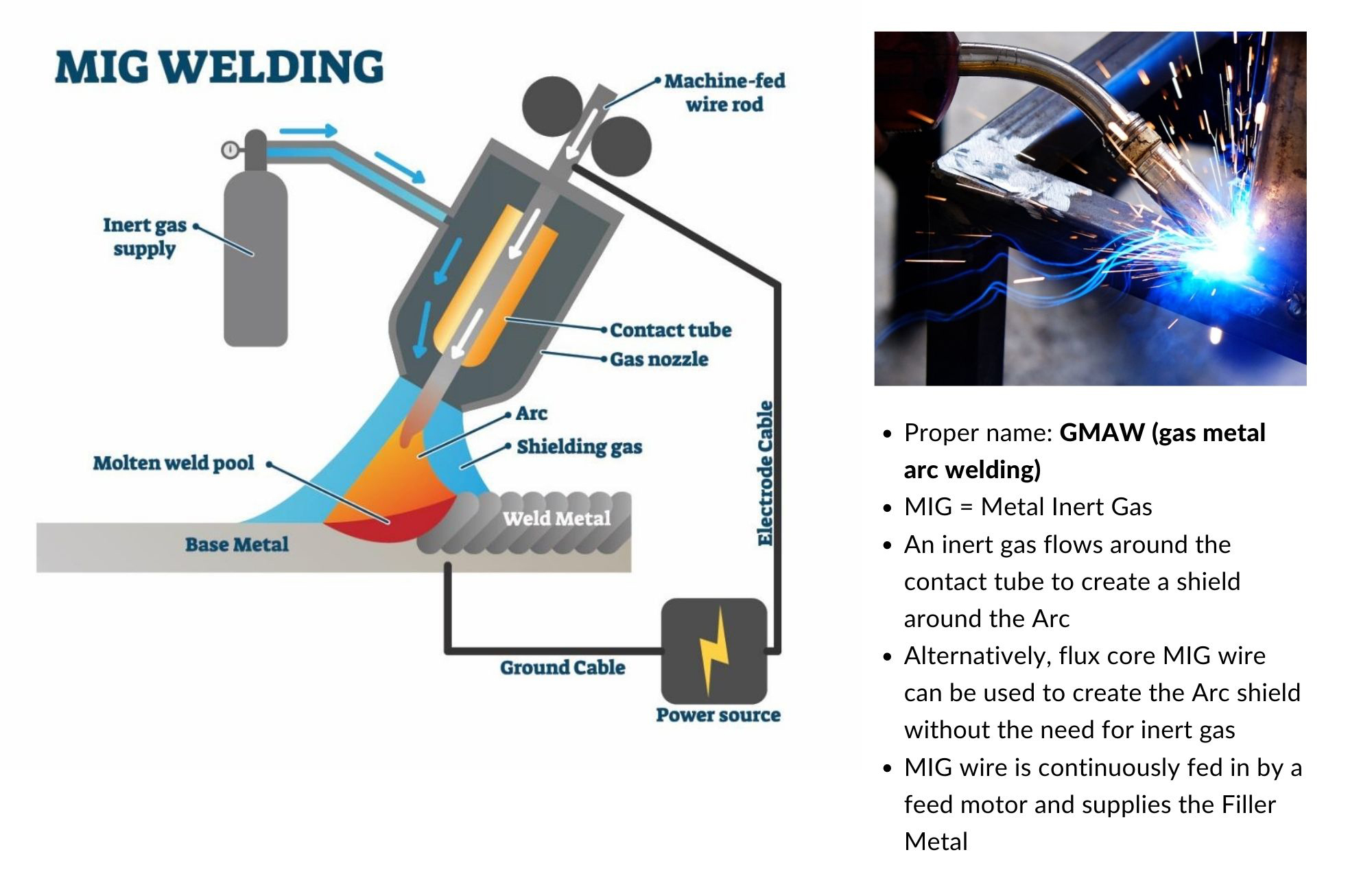

TIG Welding

In TIG welding, aka gas tungsten arc welding (GTAW), there is no continuously fed wire. Instead, the gas being funneled to a welding stick and ignited is held in one hand and the filler rod is held in the other hand. The welding arc is shielded by an inert gas fed around the tungsten electrode.

TIG welding is known for producing precise and clean welds on any metal. TIG equals tungsten inert gas. See image 2 for an illustrated explanation of TIG welding.

Image 2. An illustration of how TIG welding works.

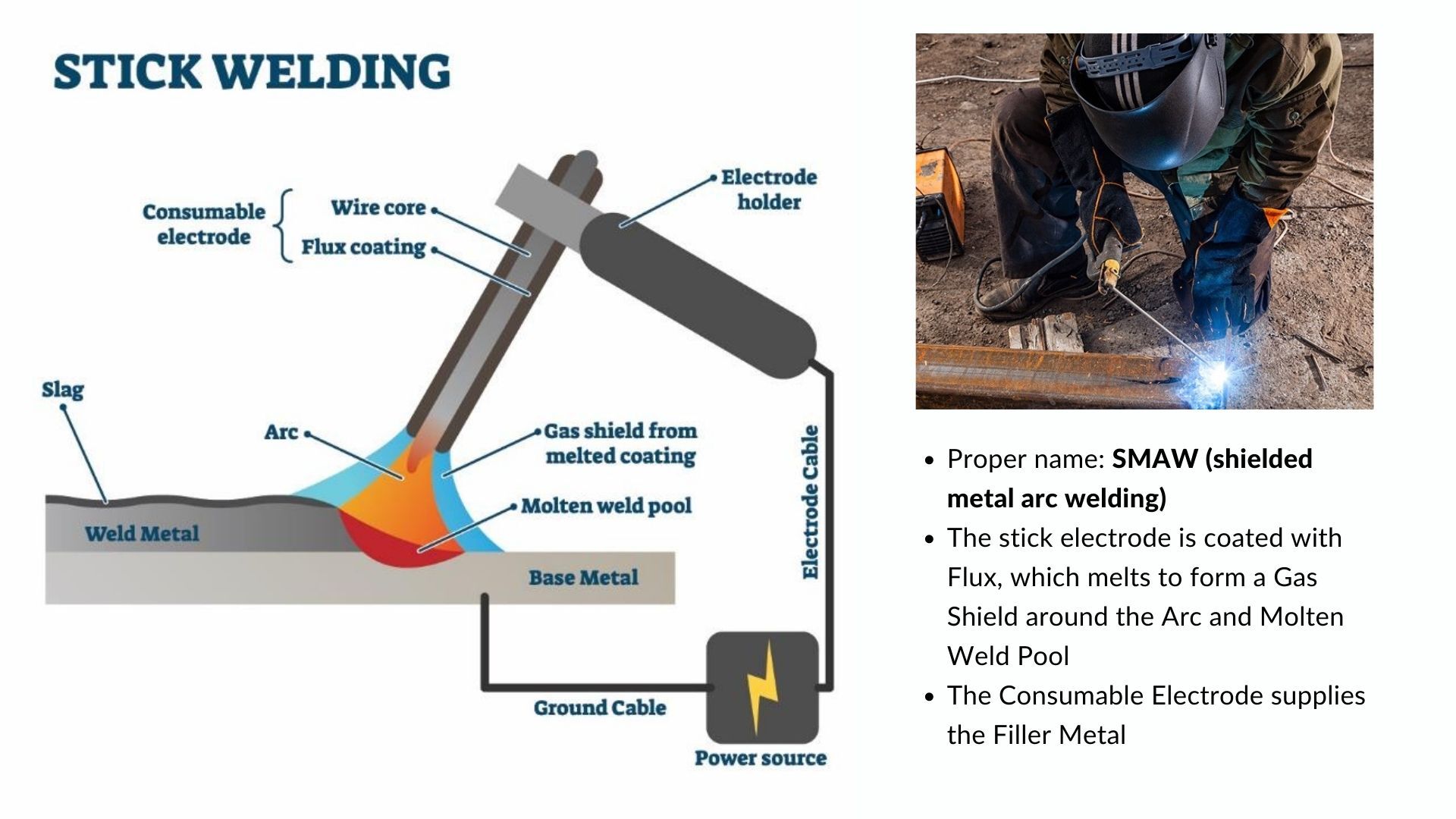

Stick welding

Stick welding, aka shielded metal arc welding (SMAW), is one of the most widely used welding processes. The stick electrode is coated with flux, which melts to form a gas shield around the arc and molten weld pool. And it works for various construction projects, heavy equipment repair, pipeline repair, and other jobs. See image 3 for an illustrated explanation of the arc welding process, which is also known as Stick welding.

Image 3. An illustration of how Stick welding works.

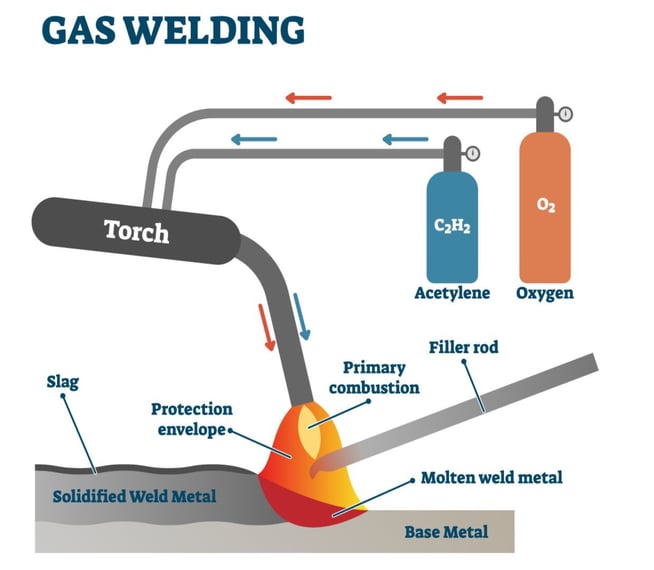

Gas Welding

Gas welding works by gas being funneled to a welding stick and ignited. Which creates a high-temperature flame that melts the filler and parent metals together. See image 4 for an illustrated explanation of gas welding.

Image 4. An illustration of how gas welding works.

Laser Welding

Laser welding is the newest option of the group and uses a high-energy beam to fuse materials together. NaiMor does not currently use laser welding.

Benefits of Welding

Welding plays a huge part in the process of metal fabrication and manufacturing because it allows multiple pieces to be securely combined together.

Welding offers many benefits for manufacturing. Specifically, it offers a durable bond, flawless seam, superior melting point, and is an efficient and versatile system for metal fabrication.

The Tools of the Trade

Welding emits an extreme amount of heat, sparks, metal slag, and can release toxic fumes. Therefore the right equipment and location is needed for safe welding.

Fire resistant clothing and a jacket specifically designed for welding is essential for protecting oneself from possible burns while working. Don’t forget the gloves and steel-toed boots either! You don’t want to get hit with the smoldering sparks that fly when welding.

A specially fabricated welding mask is also paramount as the light emitted from welding can do serious long term damage to the eyes.

Because of this, welding is unsafe to even watch from a distance without proper eye protection. Additionally, shops should use special welding screens set up around the welding zone to protect other workers from the flash that is present when welding.

A welder might want to consider a respirator if working in an area with poor ventilation.

Why NaiMor?

At NaiMor we pride ourselves on our quick response times and speedy production rates for all our finished parts. We also employ operators who have a deep knowledge base and skills to match.

At NaiMor we have WABO certified welders. Additionally, we use indestructible Siegmund weld tables that measure 7’ wide x 12’ long, with the ability to extend to 14’ long. These tables keep weldments straight and accurate. All of which enables us to deliver high quality parts on time to our customers!

One of our many Siegmund weld tables and examples of special welding screens.

NaiMor guarantees top tier work, all done in house. See our blog post for further information on our welding services!

Check out our instagram for many more photos and videos of our work!