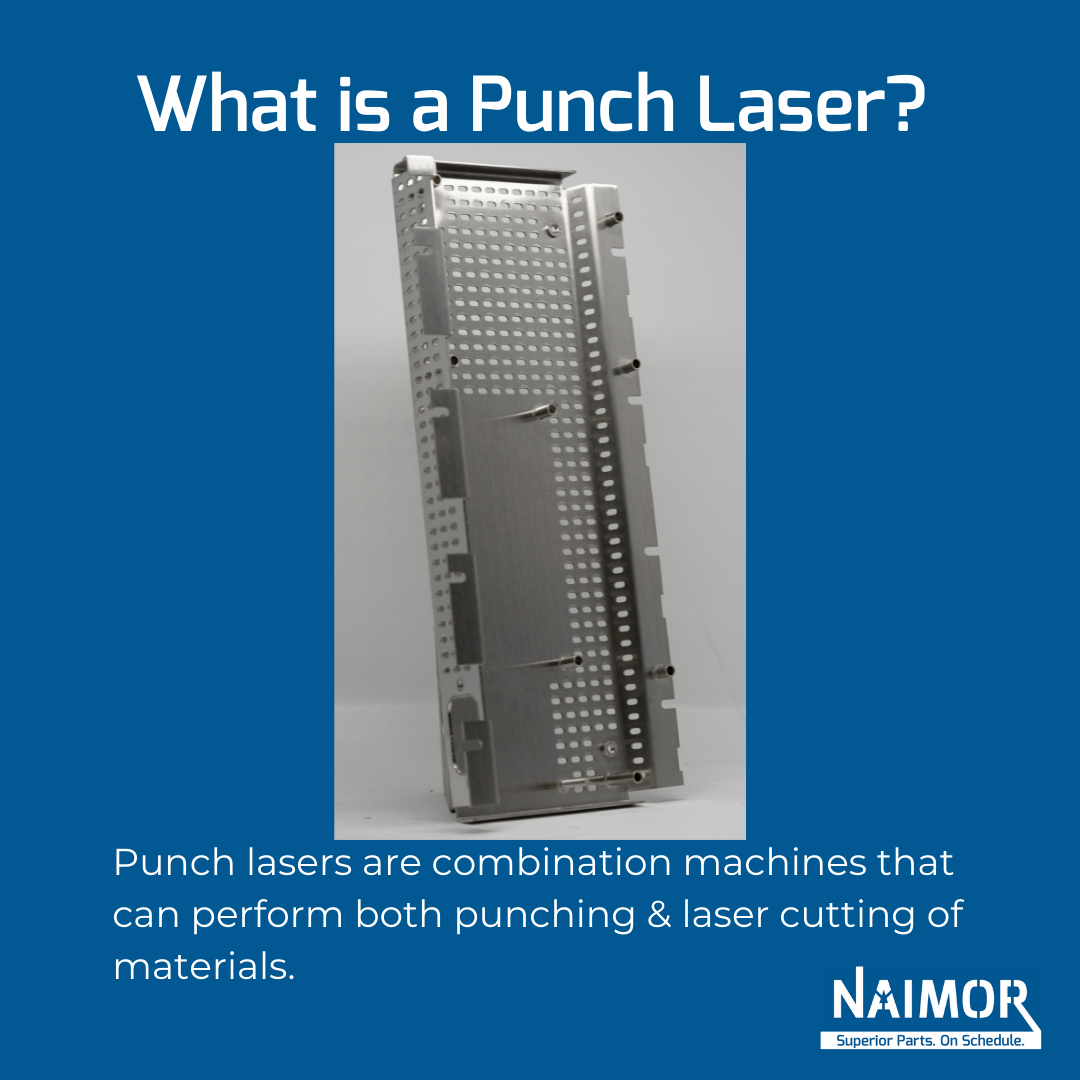

What is a Punch Laser?

Stated simply, a punch laser combines the flexibility of a laser machine with a fast turret punch machine.

Punch lasers are combination machines that can perform both punching and laser cutting of sheet metal. These machines combine the speed of punching machines with the laser’s flexibility to cut complex shapes.

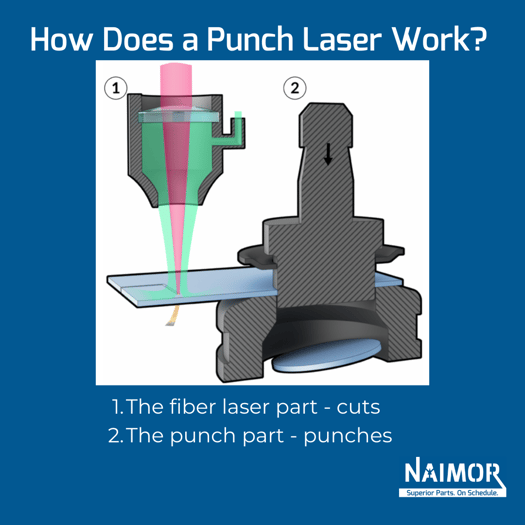

How does a punch laser work?

A punch laser has two main processes to it and uses a CNC interface to control both the punch and lasers separately. There is the laser that has the ability to cut complex inner and outer contours with perfect edge quality. The laser is able to start and stop where needed to allow it to more around the sheet and cut shapes larger and more intricate than the punching tool will allow. This results in lower tooling costs since the laser has the ability to cut any shape where punch tooling is not available.

And there is the punching head that is extremely fast with punch patterns, such as circles. This allows for small batch and high volume jobs to be done very quickly.

The punch laser has a sheet metal punching tool in the shape that needs to be cut. And uses thick turret tooling, which means it can be a single hit or a cluster tool. A cluster tool is multiple punches grouped together in one tool.

Punch tooling consists of two components: a punch on the top that is driven through the material by the striker. And the die which in a blanking operation the die is made with clearance to allow for the material being punched to clear the tool. This punching tool gets hammered on the top and punches down through the metal allowing the shape to be cut out.

There are two forms of laser cutting machines: CO2 and fiber laser.

CO2 Laser

CO2 lasers are great for cutting thicker materials. They deliver faster initial piercing times, quicker straight line cutting and a smoother surface finish when cutting materials above 0.197” (5mm).

CO2 lasers generally produce better edge quality on plate stainless and aluminum parts. And they allow greater flexibility when working with non-metal materials.

However, CO2 lasers use significantly more power and take up a larger footprint than fiber lasers. And it requires more gas and maintenance.

Fiber Laser

Fiber laser is the newer technology in cutting and is rapidly overtaking CO2 lasers in the manufacturing industry. They are relatively maintenance free machines that have a long service life.

Fiber laser cutting machines are also smaller than CO2 laser machines. These machines have increased cutting speeds by as much as 25% when compared to machines that use CO2 lasers.

NaiMor is in the process of acquiring a fiber punch laser machine to replace our CO2 punch laser machine. This will allow for increased speed of processing and allow for a wider variety of materials. In addition to improving cost and efficiency.

The Benefits of a Punch Laser

These machines have all the functionality of a turret punch with the added value of a laser. They also reduce the time delay associated with secondary operations. Modern punch lasers have the ability to perform operations that would typically need a second machine. Such as 90 degree bends, tapping holes, deburring, and other operations.

A punch laser machine is useful when projects require processes that would use multiple machines. These machines can maximize floor space, minimize work in process, and increase overall flexibility to fabricate a wide variety of parts.

These machines are also incredibly useful when a part requires many perforations. Because a laser doing many cuts next to each other will deform the metal due to the heat released from the laser.

With the punch laser, NaiMor is able to make perfectly round circles. Another benefit of the punch laser is the high speed and versatility of these machines. Because of the punch lasers' versatile functions, it allows us to process different types of raw materials in a number of ways.

Why NaiMor?

At NaiMor we pride ourselves on our quick response times and speedy production rates for all our finished parts. We also employ operators who have a deep knowledge base and skills to match.

At NaiMor we have a 33 ton punch 1.5kW laser that can handle metal sheets up to 48” x 120”.

NaiMor guarantees top tier work, all done in house. See our blog post for further information on our punch laser services!

Stainless steel parts destined for coffee machines!

Stainless steel parts destined for coffee machines!

Check out our instagram for many more photos and videos of our work!