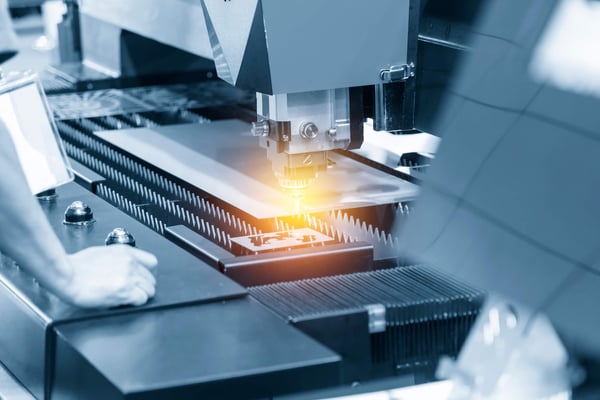

Since the advent of carbon dioxide cutting technology back in the 1980s, fiber lasers have been the next biggest and best thing introduced to the world of metal fabrication.

Fiber lasers have not only brought innovation and improved productivity to the industry, they have also made far more advances in their energy density than C02 lasers ever have.

In fact, in just 5 years, fibers lasers managed to achieve a 4-kW cutting threshold, which took C02 laser nearly 20 years to achieve. And, in 10 years, fiber lasers have managed to achieve up to 20kW ranges, which C02 lasers have yet to attain.

It’s not hard to see why, Seattle based Naimor Metal Fabrication has chosen to add a fiber laser to their inventory of equipment. With customers demanding unique designs with quick turnaround times, adding this valuable piece of equipment to our list of services provides for boosted output capabilities, expanded material options increasing our flexibility and saving our clients time and money.

The Advantages of Using Fiber Lasers

The biggest advantage our new fiber laser is that it offers our metal fabrication shop a larger cutting format of 6’ X 12’, automation, and expanded capability of cutting thicker material as well as laser cutting reflective material like brass and copper.

Furthermore, fiber lasers provide significantly faster cutting speeds, which means that our fabrication shop can reduce our client’s turnaround time.

When compared to a much larger 4-kW C02 laser, a 2-kW fiber laser provides roughly five times as much power density at its focal point. Additionally, a fiber laser also possesses 2.5 times as much absorption due to its shorter wavelengths. This combination of both, higher wavelength absorption, as well as its higher power density, means that a 2-kW fiber laser can achieve cutting speeds that are, on average, about five times faster when using materials that are less than ¼” thick. This is where the fiber laser excels. Cutting simple shapes in materials at the thinner end of the spectrum.

Although the fiber laser is very fast, its overall speed is often slowed by complex shapes or large numbers of pieces. Automated handling systems can help with large jobs by taking over the loading and unloading of materials. The laser can cut sheet after sheet, unmanned reducing machine downtime due to manual material loading.

While the laser beam that a fiber laser emits is incredibly powerful, it can also be highly focused to achieve extremely accurate levels of precision. The beam won’t cause heat damage to the surrounding material of the object they are working on. This is an important benefit when working on very small parts.

But, that’s not where the advantages of using a fiber laser stops. With much higher energy densities, fiber lasers are capable of cutting materials that are up to 1-inch thick. Furthermore, they can cut even faster when using nitrogen as an assisting gas.

Fiber laser cutting speed benefits are most noticeable when nitrogen is used an as assist gas. This is because of the fact that as the laser cuts, any molten material is quickly ejected, almost just as fast as it can be melted. So, in essence, as you approach higher power densities, the cutting material is melted even faster, which further increases the feed rate of the laser, as well as your output capacity.

Additionally, fiber lasers are great at working with reflective metals, something that other types of laser processes can struggle with. Cutting copper, and brass is much safer because the laser’s beam is not reflected to the point of origin where it would damage the laser machine. Finally, due to their lower power consumption, fiber lasers are also much more energy efficient, which can save on production costs.

Conventional C02 Lasers Vs. Modern Fiber Lasers

It’s easy to see why fiber laser are leading the industry and slowly replacing older C02 cutting technology. With considerably higher output capabilities and expanded material options, the benefits of using fiber lasers can be a game changer for any parts fabricator.

There are many advantages to fiber lasers that don’t come along with using traditional C02 lasers.

Let’s recap some of the most beneficial aspects of fiber lasers:

- Fiber lasers have higher energy densities, enabling them to cut materials up to 5 times faster than C02 lasers.

- Fiber laser operate at lower operational cost than that of a CO2 laser.

- Fiber lasers don’t need any additional warm-up time, compared to CO2 lasers which take about 10 minutes on average to warm up.

- Fiber lasers require far less maintenance than C02 lasers. There are no mirrors or lenses to clean or bellows to check, and they do not require regular beam alignments. This is in comparison to the roughly 4 or 5 hours of weekly maintenance required when using CO2 lasers.

- Fiber lasers can cut reflective materials such as stainless steel, without worrying about reflections that could damage the cutting unit.

- Fiber lasers are not subject to contaminates in its beam path. This is because they have a fully sealed beam path at both the power source, as well as at the cutting head.

- A fiber laser’s optic beam path consistently maintains its center. And, because of the fact that a fiber laser’s beam maintains its consistency, the cutting parameters also remain consistent, meaning that there are far less adjustments to be taken care of from day to day.

Still, there are some disadvantages to using fiber lasers over a C02 laser. For example, C02 lasers have a much quicker piercing time when a cut is first started. This means that they will work more efficiently when using thicker materials and are also faster when cutting in a straight line.

Is Fiber Laser Technology the Right Choice?

In essence, using fiber lasers means higher output volumes, as well as an increased machine capacity. This means that we could technically produce as much as two of our existing CO2 laser cutters with a single fiber laser. Furthermore, this can all be translated into a massive opportunity in terms of being able to output anywhere from three to four times as many parts per laser unit, which is a significant improvement over using our CO2 lasers.

Keep in mind that to keep up with our new and increased productivity capacity, our front-end systems will also be updated as well. By understanding that there will be an increased need to present cutting materials to our fiber lasers in a timely fashion, this will also drive the need for more efficient material handling, as well as an increased inventory capacity.

By using fiber lasers, we will now be able to take on projects that involve using metals such as bronze or copper, as well as many other materials that we previously did not have the ability to work with.

Faster cutting times, lower operational costs, and less maintenance all combine to increase our company’s productivity and efficiency. Custom laser cutting is one of the best ways to ensure you have a reliable and precise means of completing a project. Laser cutting has been around for a while, and many construction companies rely on CO2 laser cutting services for their projects since this tried-and-true method is an industry standard. With the addition of fiber laser cutting services, we can offer our clients new opportunities and expanded options when it comes to creating designs.

Find out more how custom laser cutting can benefit your large construction project. Contact us today!