What is Metal Finishing and Why Should You Use It?

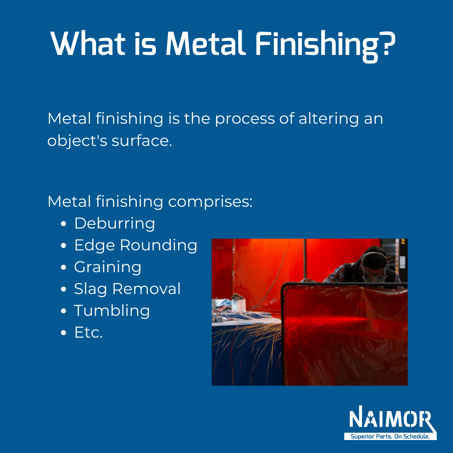

What is Metal Finishing?

Metal finishing is the process of altering an object’s surface. The reason for this process is to improve the appearance of the meta. And to prepare it for paint, powder coating, or other surface coatings. In some cases, it is also used for improving the durability of the metal.

How Does Metal Finishing Work?

Metal finishing is one of the final procedures taken in the metal fabrication process. It allows us to perfect our parts before they reach customers.

There are several different ways to do metal finishing, each offering their own benefits. These processes include: deburr, edge rounding, graining, and slag removal machines.

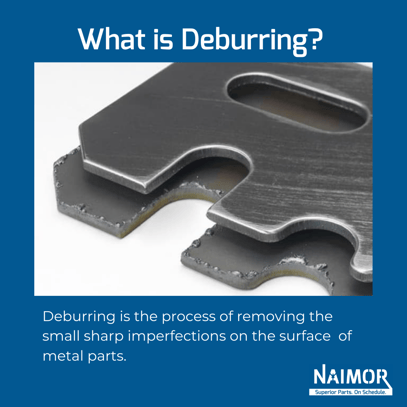

Deburring

Burrs are small, sharp imperfections on the edges and surface of parts and deburring is the process of removing these burrs. It is a cost effective method of surface finishing and produces a high quality finish.

The most common deburring machines for sheet metal are Timesaver sanders. They use a large sanding belt and a conveyor system to feed sheets through. There is a height adjustment for varying material thicknesses. A time save can process a high volume of sheets/parts quickly due to the automatic feeding system that keeps parts moving.

Edge Rounding

Edge rounding removes the vertical burrs as well as nibble marks or scallops on the holes and edges of a part that has already been deburred.

It is also used to break the edge on the processed parts. This allows for smooth metal parts which makes being able to do perfect coating and protection significantly easier.

Tumbling

In tumbling a batch of parts is put into a rotating drum with media. The media can be sand, or other abrasive material.

The parts, along with the media, are allowed to tumble in the machine for a set amount of time to achieve a softened rounded edge and a durable surface finish. This process is efficient because once the tumbler is loaded it runs without an operator needing to stand by.

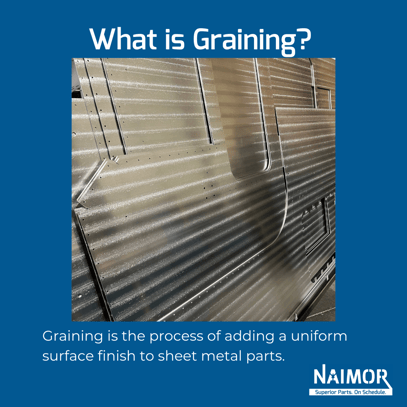

Graining

Graining is the process of adding a uniform surface finish to sheet metal parts.

Different size grit or different types of abrasives may be used to create different graining effects. A sheet of metal is passed through a belt sander on a conveyor belt and inside the sander a belt coated with abrasive spins on two cylindrical drums.

A CNC router can also be used to grain sheet metal. It does this by swapping the tool to a circular steel brush. Which then runs over the surface of the metal to create the grain.

Industries that may use metal graining include home appliances, aerospace, automotive, food processing, machinery, hardware, recreational, and architectural.

Slag Removal

Slag is the by-product of cutting certain metals. If not removed before the metal cools, the slag solidifies on top of your steel. Making your part rough around the edges and marked with burrs.

One of the best ways to remove slag is with a special machine. This machine is faster and safer than using angle grinders on a part.

Unfinished parts are fed through the machine. Which then runs parts through a high speed drum and then a highly flexible, diamond-profiled roller.

The roller rounds off the edges of parts as well. After the grinding portion is complete, parts are then passed over by a high-density steel wire brush. This removes any remaining sharp edges.

Why Metal Finishing?

A part that contains burrs or slag is flawed. These imperfections compromise the functionality, lifespan, and safety of a machined part. And they can cause numerous quality and appearance issues.

Why NaiMor?

Did you know that metal finishing can account for 30 to 35% of the manual labor costs?

However, these costs are drastically reduced when a metal fabrication shop invests in the specialized machinery required to efficiently complete different metal finishing processes.

We have invested in several different specialized metal finishing machines and therefore are able to offer lower labor costs, ensure higher part quality, and increase worker safety!

At NaiMor we pride ourselves on our quick response times and speedy production rates for all our finished parts. We also employ operators who have a deep knowledge base and skills to match.

NaiMor guarantees top tier work, all done in house. See our blog post for further information on our metal finishing services!

Check out our instagram for many more photos and videos of our work!