How Superior Precision Forming Can Help Reduce Cost and Increase Product Quality

When it comes to manufacturing, processes can always be refined. Obviously, one of the most important aspects is how products are made and produced. From a designing perspective, however, one of the greatest challenges is to create something out of nothing. A prototype of a new machine or product can be a daunting task, and the cost of doing so can be quite prohibitive.

Fortunately, precision forming can be a hugely beneficial solution, and help you bring more designs to fruition at a fraction of the cost. Below we’ll be discussing precision forming and how it can help you succeed.

What is Precision Forming?

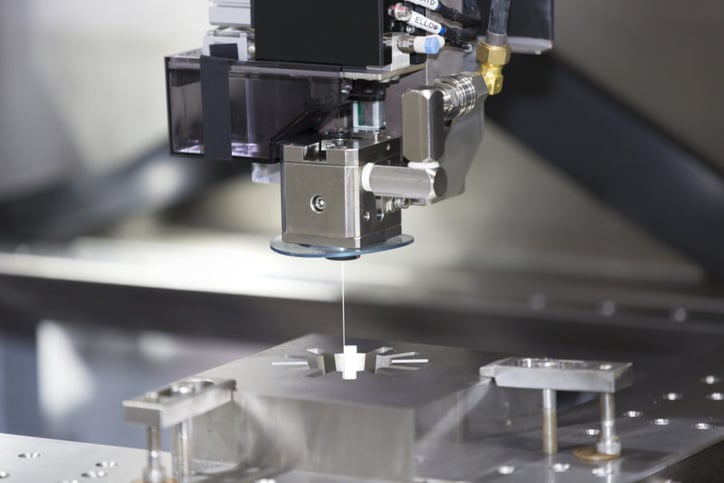

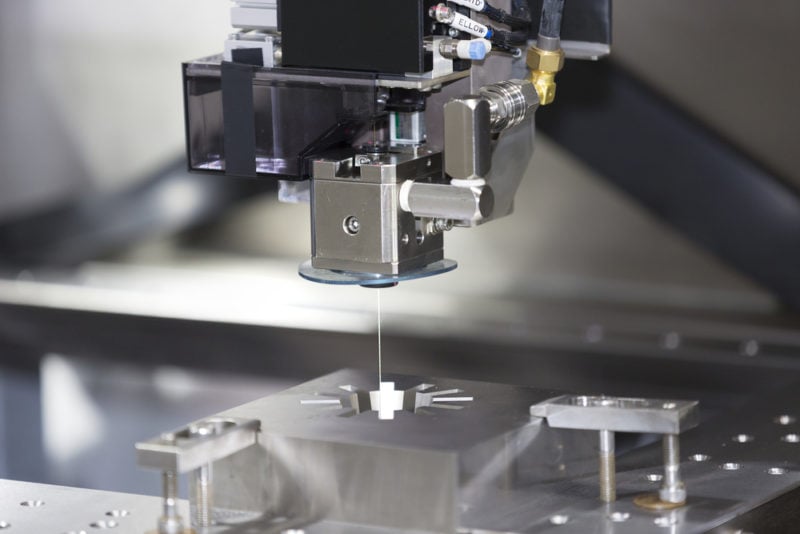

At its core, precision forming is when you create a product using sophisticated techniques such as lasers and stamping. 3D printing is another form of precision forming, as it builds your item from scratch rather than shaping it out of current materials.

When creating a new design for a product, it can take a long time to get a prototype up and running. This is usually due to the cost of building something using traditional methods. Precision forming can alleviate this problem by using techniques that are conducive to individual production, rather than mass production. Stamping, lasers, and printers are some of these methods.

Building to Scale

Another benefit of precision forming is that you can create smaller working models of something that will be much larger in reality. While building the real thing would be too cost prohibitive, making it to scale at a fraction of the size can be much easier and provide the same results. This will also allow you to run tests that would otherwise be hypothetical without a working product.

Faster Turnaround Time

Depending on your needs and the sophistication of the techniques, precision forming can usually be a much quicker operation than traditional manufacturing. Bring your ideas up to speed without getting bogged down in the particulars of how to make it. Since you have a working prototype, you can ensure that your production schedule doesn’t fall behind.

Less Investment

We’ve already discussed how this process can save you money in the long run, but it also ensures that you don’t spend too much time working on a prototype as well. A rapid prototype enables you to see what changes need to be made and fix any issues much more proactively without sinking too many resources into the project. Precision forming can give you the option of seeing what could go wrong before you commit to anything substantial, saving you a ton of headaches down the line.

More Flexibility

Because of the sophistication of the techniques, you will be able to come up with new designs and schematics that can be applied to a prototype, even if large-scale production is not possible yet. This can also show you what types of problems would occur in creating a “real world” model without any of the real danger. Overall, precision forming enables designers and creators to think more creatively and push boundaries. This is where innovation lives, and this process helps cultivate better ideas.

Easier Scaling

If making a prototype design was cost prohibitive before, that also meant that it was harder to determine the cost of scaling up production. Fortunately, precision forming can be used for whatever scale you like, so once your preliminary design has been tested and approved, you can then roll it out much more easily. Now, instead of dealing with intangible variables, you'll have hard numbers on which to base your data.

Precision Forming in the Future

As technology advances every day, the process of building new products is becoming faster and more integrated. Precision forming can utilize new automated processes that deliver better results, especially if you decide to go into full production.

Overall, we are seeing much more of this kind of manufacturing take place than ever before. As more people start to see the benefits of doing things this way it will only become more ubiquitous, which will, in turn, grow precision forming to become even better. One method that is sure to dominate the landscape in the coming years will be 3D printing, as it outshines other manufacturing procedures by a long shot.

Get A Project Quote

In the end, if you are looking for a simple and effective way to bring your designs to life, precision forming is the best way. Naimor, Inc. specializes in manufacturing component metal parts in a huge array of sizes and shapes. Our skilled technicians work closely with you to produce parts to your exact specifications. Whether you’re an architect looking to create a scale model or a company trying to test a new product, this type of forming will help you succeed much more than you thought possible.

Contact us for a free project quote today!