What is Machining and what are common techniques?

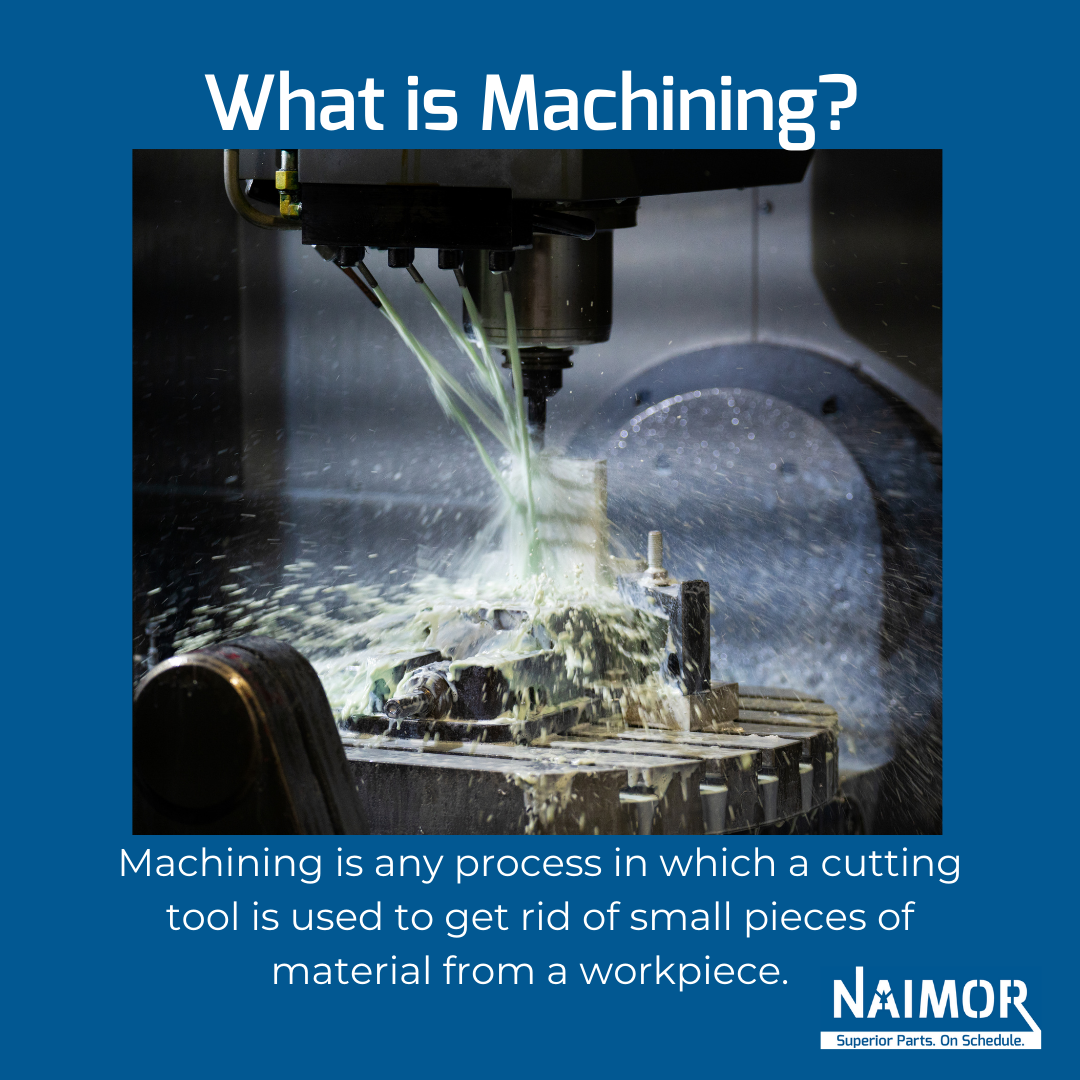

What is The Process of Machining?

Machining is defined as any process in which a cutting tool is used to get rid of small pieces and chips of material from a workpiece. Machining is used to cut and subtract materials, typically metal, but also wood, plastics, and polymers by a machinist.

Machining is a process that is used to make simple to complex shapes by precise removal of material to create parts for tools, machines, and more. Some types of equipment and machine tools used by machinists are mills, lathes, and drill presses. This type of equipment is used for shaping different materials into parts using precision cuts with high tolerance rotating cutters.

This process is used to make specific and detailed parts and tools for engines, appliances, mechanical projects, medical industries, aerospace and more.

Types of Machining

Some of the main types of machining include milling, drilling, boring, reaming, and turning. There are a variety of other processes that are considered machining but within the modern machining processes, these are the most relevant types of machining.

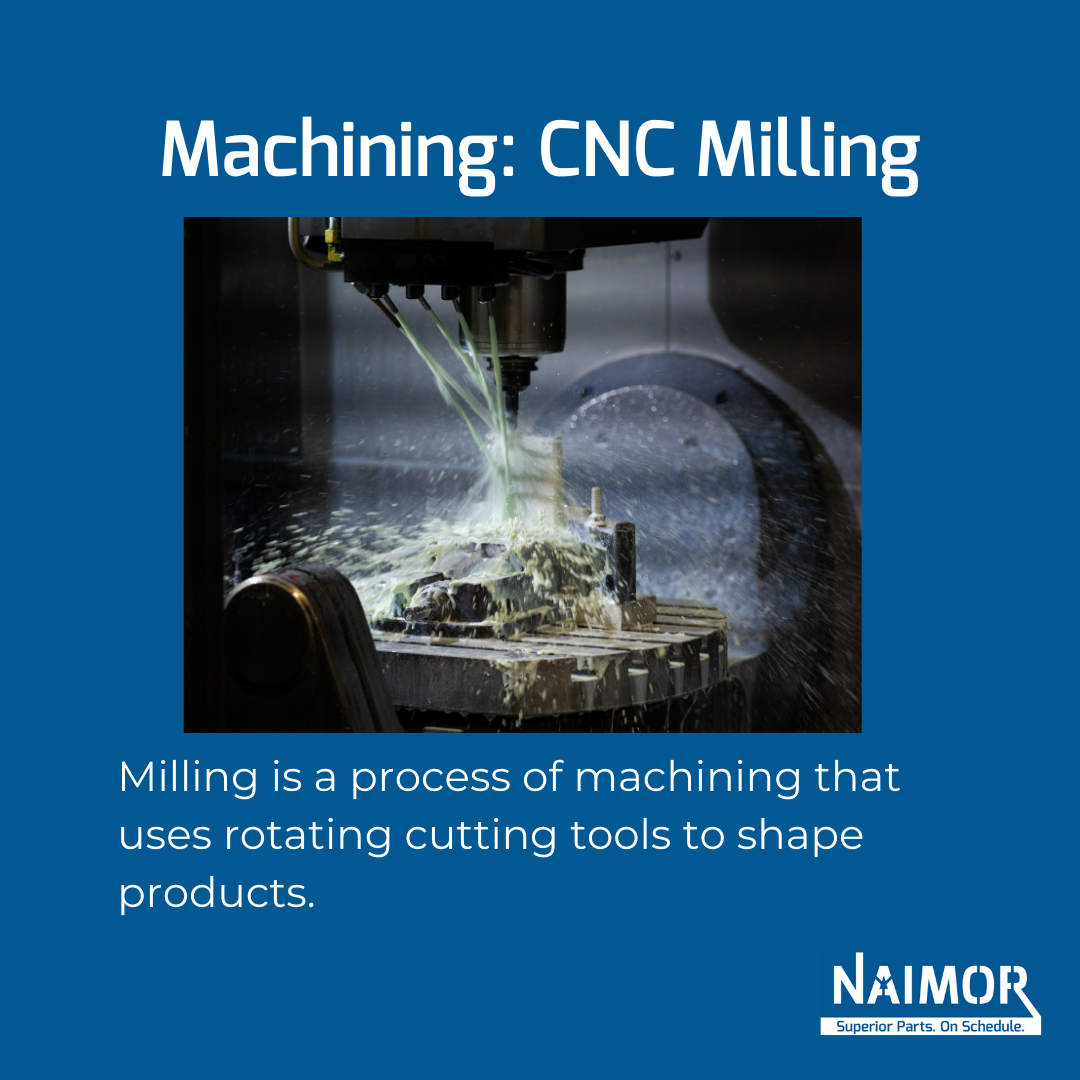

CNC Milling

Milling is a process that uses rotating cutting tools and a CNC (Computer Numeric Control) to allow precise repeatable actions of a given workpiece. This is the most useful tool because it is the most versatile one that is regularly used in a machine shop.

Drilling

Drilling is the process of creating a new hole or refining an already existing hole using a cutter that rotates. Drilling is normally done with a drill press but can also be done with drilling tools that are attached to mills or lathes.

Turning

Turning is the process where the workpiece is turned, and the tooling remains stationary. This process is used for making cylindrical parts. By rotating the workpiece, it results in a more concentric part. This process is often related to wood products such as baluster pieces for stairs, and the manufacture of baseball bats.

In a metal shop, turning is used for drive shafts, connecting rods, and for creating long running threaded components. Most turning is done on lathes, and modern lathes may also incorporate drill tools to drill cross hole features to further compliment versatility in part creation.

Boring

Boring like drilling is a commonly used process, boring utilizes a predrilled hole and by use of specific tooling opens the hole up to a desired final size by using a cutter that scrapes away at the wall of the hole in a cylindrical pattern to maintain roundness and concentricity.

Reaming

Reaming is a process that uses a size specific specialized cutter, called a reamer, to open a predrilled hole to a specific size. Unlike boring that may use an undersized tool to open the hole, in reaming a full-size cutter is passed through the bore, leaving a straight even wall at the desired final size.

Machining Techniques

The two main techniques that are used most commonly are subtractive and additive manufacturing. Machinists use these techniques to take away or add material to various parts.

Subtractive

Machining is a process that makes the wanted shape by getting rid of material that isn’t wanted off of a larger piece of material. Because a part is created by taking away material from a bigger piece of material, this process is known as subtractive manufacturing.

Additive

3D printing is a new approach to the production process that allows the creation of a 3D object using a digital model. Other additive methods exist as well. Such as selective laser sintering (SLS), fused deposition modeling (FDM), and others.

Common Tools Used in a Machining Shop

There are a variety of machining tools and they can work together with other tools at different steps of the manufacturing process or even work alone. Many tools that are used in a machine shop have detailed and specific uses, but others are very versatile and can be used for many different things.

Cutting tools

Cutting tools that are used in a machine shop are devices such as shears and saws. These are used to cut materials that have predetermined dimensions and specificities, like sheet metal.

Boring tools

Boring tools are tools that are used to enlarge as well as reshape an already established hole. Machine shops sometimes use jig borers to easily and accurately find a hole’s exact center. Shops may also use a horizontal boring machine to make the cut.

Drilling tools

Drilling tools are devices that rotate to make holes that are round on a workpiece by getting rid of material. Machine shops may have specific drill presses for hole making or specific tools that are able to be attached to machinery like lathes or CNC machines.

Turning tools

Turning tools are tools that rotate different workpieces while a cutting tool gets rid of the unwanted material, making it into the desired shape. Horizontal lathes are the most commonly used types of turning machine that is used in a machine shop.

Grinding tools

Grinding tools are tools that make light cuts using a rotating wheel. Grinding tools are also used to sharpen tools and create a finish on an already machined workpiece. The most commonly used grinding tool is a pedestal grinder.

Pedestal grinders are used to sharpen cutters on turning and milling machines. These tools are also able to deburr and remove any imperfections on the surface of a workpiece. Using grinding tools as a form of deburring allows the tools to create a smooth finish.

Milling tools

Mills use rotating cutting surfaces with a range of blades that create holes or cut designs out of material. The milling machine is then used to mill irregular and flat surfaces. Milling machines are also used to cut, bore, drill, and make slots on a workpiece. And they come in various configurations, such as vertical and horizontal, to cater to different tasks and workpiece orientations.

How Does the Machining Process Work?

Unfinished workpieces that need machining are pieces that require some material be cut away. Some parts need machining to create a finished product.

One example of machining is a piece may need to have a very specific outside diameter. In this case, a lathe machine tool is used to make the diameter. The lathe machine tool does this by rotating a metal workpiece for a cutting tool to cut the excess metal. The lathe tool creates smooth and round surfaces that are necessary.

Why NaiMor?

At NaiMor we pride ourselves on our quick response times and speedy production rates for all our parts. We also employ operators who have a deep knowledge base and skills to match.

Here at NaiMor, we have several mills. See our blog post for further information on our CNC machining services.

NaiMor guarantees top tier work, all done in house.

Check out our instagram for many more photos and videos of our work!

LEARN WHAT NAIMOR CAN BUILD FOR YOU!